Advertisement

Quick Links

Advertisement

Summary of Contents for LG 42V5

- Page 1 PDP Instruction Manual for customers Model 42V5 ver 1.01...

- Page 2 ONTENTS INTRODUCTION PRECAUTIONS BASIC TROUBLE SHOOTING This manual is for the 42” V5 model. Basic rules are same with 42” V5 for other models.

- Page 3 1. Introduction 1.1PDP module PDP module is composed with PANEL part and DRIVE part. Panel is consist of electrode, phosphor, dielectric, gas. And drive part is made up of electronic circuit (X , Y-sus, Z sus, Y drv,PSU,CTRL B/D) and PCB. 3 /39...

- Page 4 2. Let customers can distinguish module defect(LG Electronics defect) and a defect from their work by educating an early analysis for SET maker .So customers can decide easily whether it is LG defect or customer’s. 3. Prevent defects which is made during set assembly process previously by educating Work precautions and conditions.

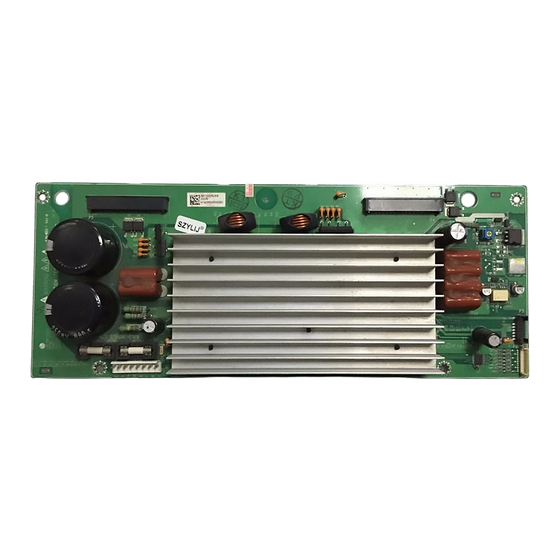

- Page 5 1. Introduction 42 inch V5 MODEL. Y DRV TOP Z-SUS B/D Y-SUS B/D Y-DRV BTM X-RIGHT B/D X-LEFT B/D CONTROL B/D 5 /39...

- Page 6 COF long 2-7 ▶ PDP Module S/N When you request LG to repair PDP module, Please inform LG the Module S/N for tracking the module’s history by e-system ① ① Model Name ② Bar Code (Code 128, Contains the manufacture No.) ②...

- Page 7 1. Introduction ▶ Voltage label (Attached on back side of module) ▶ Part No. label (Attached on board) BOARD ASS`Y PART NO. BOARD NAME BOARD SERIAL NO. PCB PART NO. ▶ COF serial No. label (attached on COF) COF SERIAL NO. 7 /39...

- Page 8 1. Introduction ▶ Terms of defect Add short (light on) Add open (light off) Sus short (light on) Sus open (light off) Add bar (light off) Mal discharge Cell defect Add short (light on) 8 /39...

- Page 9 2. Precaution 2.1 Safety precautions ▶ Be sure to read this before repair. When using/ handling this PDP module, Please pay attention to the below warning and cautions. 1. Before repairing there must be a preparation for 10 min. 2. Be aware of metalic particles to prevent short circuit . 3.

- Page 10 2. Precaution 2.3 Handle with care (COF) COF is the most important component in the PDP module. Even a little imperfection of COF can make a serious screen problem. TEARING These must not happen in assemby process These must not happen in assemby process BEING PUSHED...

- Page 11 3. Basic 1. X B/D : X board have two kind of funtion one is an addressinng and another is a path. It receives LOGIC signal from CONTROL B/D and make ADDRESS PULSE(generates Address discharge)by ON/OFF operation of FET , and supplies this waveform to COF(data) as a path.

- Page 12 3. Basic 2. Z sustain B/D : make SUSTAIN PULSE and ERASE PULSE that generates SUSTAIN discharge in panel by receiving LOGIC signal from CONTROL B/D. this waveform is supplied to panel through FPC(Z). *composed with IPM,FET,DIODE, electrolytic capacitor ,E/R coil. * IPM (Intelligent Power Module) E/R(Energy recovery) 12 /39...

- Page 13 3. Basic 3. Y drive B/D 1) This is a path to supply SUSTAIN ,RESET waveform which made from Y SUSTAIN B/D to panel through SCAN DRIVER IC. 2) Supply a wave form that select Horizontal electrode (Y SUSTAIN electrode) sequentially.

- Page 14 3. Basic 4. Y sustain B/D : generates SUSTAIN,RESET waveform, Vsc(SCAN)voltage. and supplies it Y DRIVER B/D. * Composed with IPM,DIODE, electrolytic capacitor ,FET. 5. Control (logic) Board : creates signal processing (Contour noise,reduction ISM,..) and an order of many FET on/off of each DRIVER B/D with R,G,B each 8bit input.

- Page 15 3. Basic 6. FPC (Flexible Printed Circuit) : supply a driving waveform to PANEL by connecting a PAD electrode of PANEL with PCB(Y and Z). * there is two type of this for Y B/D. One is single-sided, another is double-side. These are having pattern on it * for Z B/D, there is no pattern , single-sided, and Beta type(all of copper surface).

- Page 16 1) FPC + Heat /Sink ⇒ FPC for COF must have a Low Spec decline with getting damp 2) CHIP resistor + CHIP CAPACITOR * 42 V6 COF is the same as 42V5. 3) BARE IC (STV7610A/WAF) + GOLD WIRE/AL WIRE 4) EPOXY MOLDING...

- Page 17 3. Basic 9. IPM(Intelligent Power Module) : composition HEATSINK,CAPACITOR DIODE IC LINEAR RESISTOR, TRANSISTOR, FETS. : description Attached at Z B/D and Y B/D, make Sustain waveform. Sustainer : supply a square wave to panel to make a video. Sustain Step 17 /39...

- Page 18 4. Trouble shooting. Fast check up defect Check model No. of module , all connectors and cables. No display? Check panel appearance Check all FUSE. Check PSU output (Va,Vs,5v). (Include exhausting tip, GLASS crack) Check Y, Z b/d input voltage Replace ctrl b/d Replace Y, Z b/d vertical defect?

- Page 19 4. Trouble shooting. Logical judgment What kind of defect ? No display? Please follow the no display trouble shooting. Bar defect appeared? vertical defect? Please follow bar defect trouble shooting. Line defect Horizontal defect? Please follow the line defect trouble shooting. mal –discharge Please follow the mal discharge trouble shooting.

- Page 20 4. Trouble shooting. No display Check each section with following method if there is problem, replace or repair that part. If not go to the next section. 1. Connector Confirm every Connector (PSU, Y-SUS, CTRL, Z-SUS) ⇒ module may not be normal by mis-connection which can not send signal and power. Also Mis connection for a long time has a specific b/d failed.

- Page 21 4. Trouble shooting. 2. Exhaust tip Crack Confirm exhausting Tip and find Crack with eyes to check the vacuum state of panel. If there is problem replace the module . ⇒ in case of vacuum breakdown, module makes a shaking noise because of inside gas ventilation. (there may be a small crack which could not see with naked eyes.

- Page 22 4. Trouble shooting. 3. PSU(Power Supply Unit) 1. Check each unit part of PSU inside with naked eyes. (capacitor, FET, a kind of IC, resistor) 2. Check SW on Normal. 3. Check Output voltage which is converted from AC V SW Normal to DC V.

- Page 23 4. Trouble shooting. Diode Input voltage P300 4. Ctrl B/D 1. Confirm LED D17(flashing) ,13 lighting 2. If not CHECK OSC X1 output. 3. Check CTRL input voltage. 4. CHECK 3.3V, 5V. 5. Check IC 404 3.3V IC 54 2.5V OSC(X2) Probe Touching...

- Page 24 4. Trouble shooting. Vscw 5. Y-sus B/D Vsetup 1. Check FUSE [FS2(Va) ,FS3(Vs)]. 2. Check voltages(Vsetup,-Vy, Vscw) 3. Check DIODE between GND and Y SUS output. [SUSUP(OC2) SUSDN(OC1)]. forward=0.4 ,reverse=OVERLOAD. setup 4. Check whether output voltages agrees with voltage that represented in label. F2(Vs) FUSE 6.3A setdn ▶...

- Page 25 4. Trouble shooting. 6. Z-sus B/D 1. Check the FUSE. 2. Check input voltages.(Va, 5V,Vs) 3. Check FPC out put diode value. 4. Check ramp waveform. ▶ ▶ ▶ Check the FUSE Check input voltages Variable resistor of Z RAMP waveform slope. Va FUSE 6.3V Vs FUSE 6.3A Variable resistor...

- Page 26 4. Trouble shooting. <FPC Separating> ▶ ▶ ▶ Separate the fixed Screw of Z-Board. Pull FPC Connector Condition in Lock part is pulled Pull out Lock as shown in arrow. as shown in arrow. 26 /39...

- Page 27 4. Trouble shooting. Power protection ◎ It is power protection when power is off automatically within 2~3 min. from power on. Power protection function protect the boards when occurred short on circuits of PDP module or power problem. If can not impress power even after replacing PSU, find out where the short occurred. * PSU makers.

- Page 28 4. Trouble shooting. Vertical defect (bar) Check each section with following method if there is problem, replace or repair that part. If not go to the next section. 1. Connector Check COF connector. If not connected well,it will Make a bar defect . Check here Check here 28 /39...

- Page 29 4. Trouble shooting. 2. Checking COF Confirm whether COF was torn. And then check input of COF resistor and IC. COF 6 is torn partly Tearing <COF Separating> Lift up lock as shown Pull COF in narrow. as shown in narrow. 29 /39...

- Page 30 4. Trouble shooting. Checking address COF input of resistor and IC ◎ ▶ COF resistor checking Check the both side of resistor With Digital multi meter(DMM) . If the resistor is normal, the resistor value will be 10.2 ~ 10.8 Ω But if not, the value will be 0 or infinity and replace the resistor.

- Page 31 4. Trouble shooting. Checking address COF input of resistor and IC ◎ ▶ IC input checking Inside of IC , there is 4 ea diodes which separated in 2 series . (input 2, output 2) ▶ how to check 1.contact DMM + terminal to a right terminal of condenser(GND) and DMM - terminal to a right terminal of IC, normal value is 0.68 (fig.1)

- Page 32 4. Trouble shooting. 3. Ctrl B/D CTRL B/D supplies video signal to COF. So if there is a bar defect on screen, It may be the ctrl b/d problem. <Diagram of ctrl b/d> A flow of address signal In this figure, we can easily suppose ASIC what will be appeared on screen when a specific part failed.

- Page 33 4. Trouble shooting. Vertical defect (line) In case of 1 line open or short , check foreign substances in COF connector. First blow up the connector with your mouth to remove foreign substances which may be on it. And then if the same line appears, replace the panel.

- Page 34 4. Trouble shooting. line defect from each parts • Case 1: Buffer IC fail 16 line open COF IC 1,2 ⇒ 192 line(96+96) open. COF IC 3,4 ⇒ 64 (16 ⅹ 4)line open (with fixed interval there is on,off ……. Repetition) •...

- Page 35 4. Trouble shooting. Horizontal (bar) Most horizontal defects can be repaired. In case of adherence part of the Film and rear panel electrode defect or panel electrode open,short , replace the panel. 1. Connector It can make a horizontal bar that connector on Y b/d and Z b/d did not plugged well. Because sustain voltage can not be supplied to panel.

- Page 36 4. Trouble shooting. 2. Scan IC check Check diode value of the right side part of output pin. Normal diode value. (in case of TI IC =0.6 ~ 0.7) Defect diode value= 0.018 * It can be different from each IC Maker. Check here with DMM(either forward or reverse is ok) DMM + DMM -...

- Page 37 4. Trouble shooting. Horizontal (line) 1. Check FPC In case of horizontal 1 or more line, it is due to FPC or panel inside .ctrl b/d, Y b/d is just normal. First , sweep the FPC electrode with a clean cloth or blow up the electrode to remove particles. And then check the FPC and panel with your eyes.

- Page 38 4. Trouble shooting. Mal-discharge Most of mal-discharge appearance is problem of y drv ,y ,z b/d.check these boards when occurred. Checking order 1. Confirm Y, Z SUS signal cable. 2. Check Y DRV IC FAIL 3. Check Y sus b/d voltages(-Vy.Vscw) 4.

- Page 39 4. Trouble shooting. How to check IPM ◎ Forward : test 1: GND(+) , Sus-out(-) 2 : Sus-out(+),Vs(-) 3 : ER-DN(-),ER-COM(+) 4 : ER-COM(-),ER-UP(+) when each 4 TEST Diode value is over 0.4V => OK Reverse : test 1 : GND(-) , Sus-out(+) 2 : Sus-out(-),Vs(+) 3 : ER-DN(+),ER-COM(-) 4 : ER-COM(+),ER-UP(-)

- Page 40 Attached #1. Global Quality Information (GQI) #SAMPLE No. : TT-2004-DP4220LV-001 Set Model MP-DP4220LV Quantity □ Vertical Line ( R , G , B Pattern) □ Vertical Bar ( R , G , B ) Set Serial No. PT420200099 □ Horizontal Line ( R , G , B ) □...